Omni Block

Omni Block is a unique block that is multi-layered with constricted cross webbing that create individual cells that are filled with foam insulation inserts. It is a stand alone wall system that should not be furred, additionally insulated or sheetrocked.

Contact UsIt is recommended to plaster the interior of the block with standard sheetrock compound to exactly match any adjoining interior sheetrock walls.

Omni Block can also be left exposed on the interior, exterior or both. This type of construction economically provides finish options that other types of construction cannot provide.

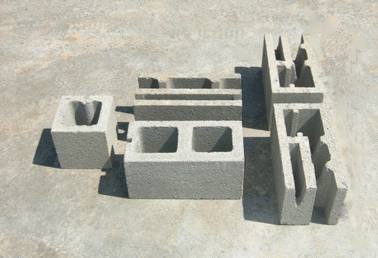

The complete Omni Block System 8 is depicted above. It consists of five types of block, the Omni Stretcher unit is the most commonly used. There are two other Omni Block units, the Omni Left Corner/Jamb and Omni Right Corner/Jamb, which are alternatively used at corners, in-line piers, and window and door jambs. Also required at window and door jambs are the standard 8″ x 8″ x 8″ half block. There are a few situations that call for a closed-ended block on both ends and that is where a standard 8″ x 8″ x 16″ is used.

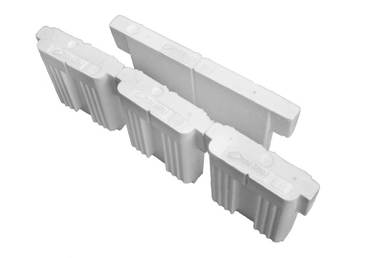

The inserts come in two sizes; Long and Short. Each fits into its corresponding block cavity. The inserts are 3/8″ taller than the block in order to insulate the horizontal mortar joints. The vertical mortar joints are insulated due to the overlapping feature (from block-to-block) of the short insert. The “whole wall” is insulated, not just individual block.

The inserts are Expanded Polystyrene (EPS) and not only provide excellent insulation, but have other favorable properties such as; they are non-toxic, do not “out-gas”, have minimal flame spread characteristics, and are manufactured with a closed looped steam process that has virtually no carbon footprint on the earth.

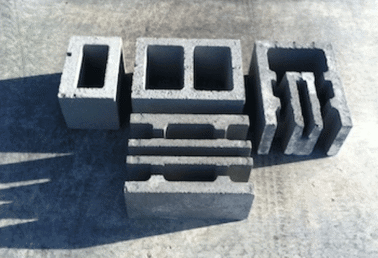

In addition to standard grey block, most distributors can integrally color, score, burnish, and split Omni Block, all providing lasting finishes that dramatically decrease life cycle costs.

Locally quarried aggregates will produce a variety of standard colors at local production plants. Custom colors with special aggregates are also available.